Understand how multi-cavity die moulds help manufacturers scale production efficiently. This blog covers mould efficiency, reduced cycle times, improved productivity,...

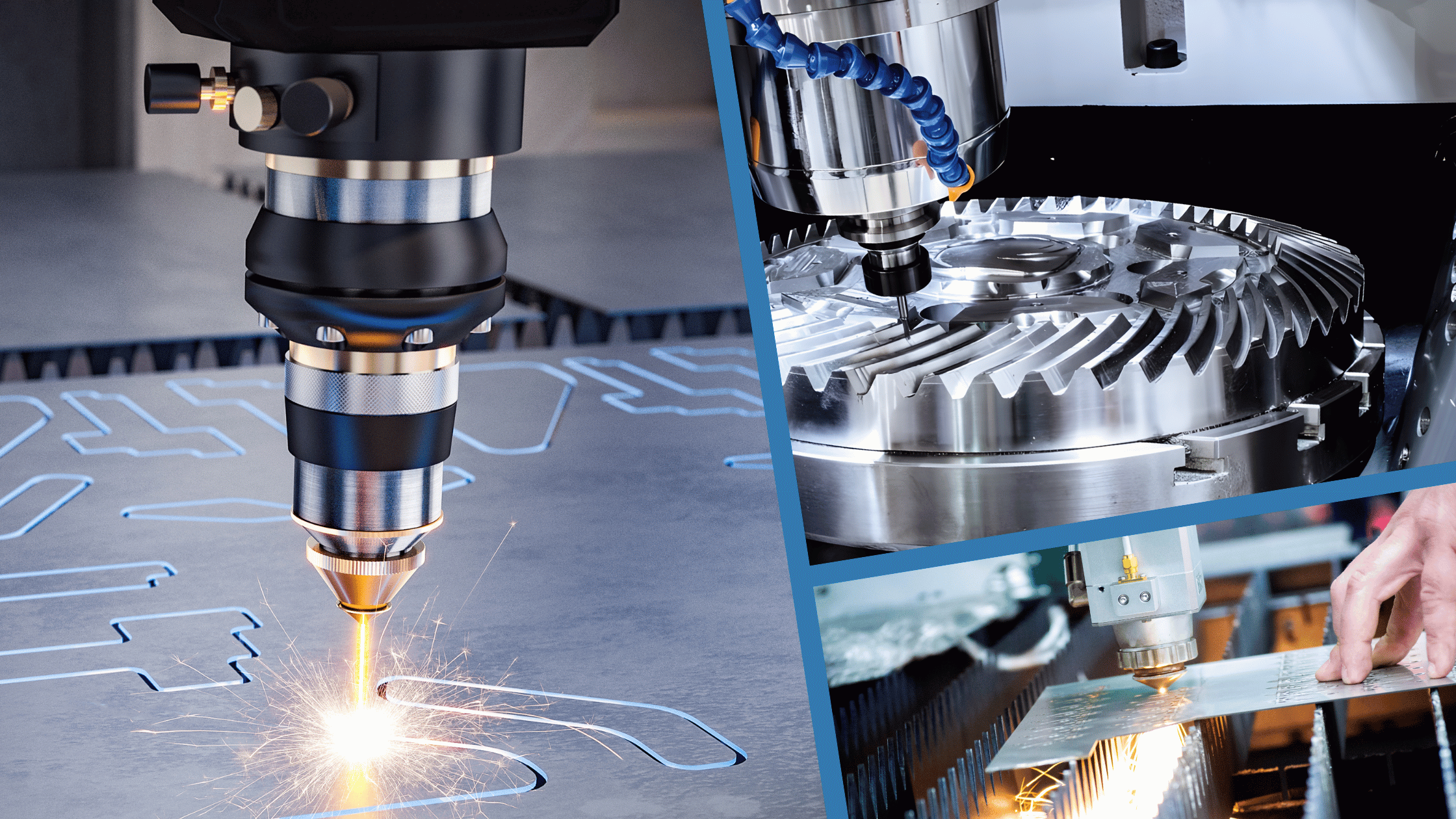

High-accuracy components, die-mould assemblies, laser cutting and turning services — engineered for aviation, pharma, defence, textile, and automotive industries.

High-accuracy components, die-mould assemblies, laser cutting and turning services — engineered for aviation, pharma, defence, textile, and automotive industries.

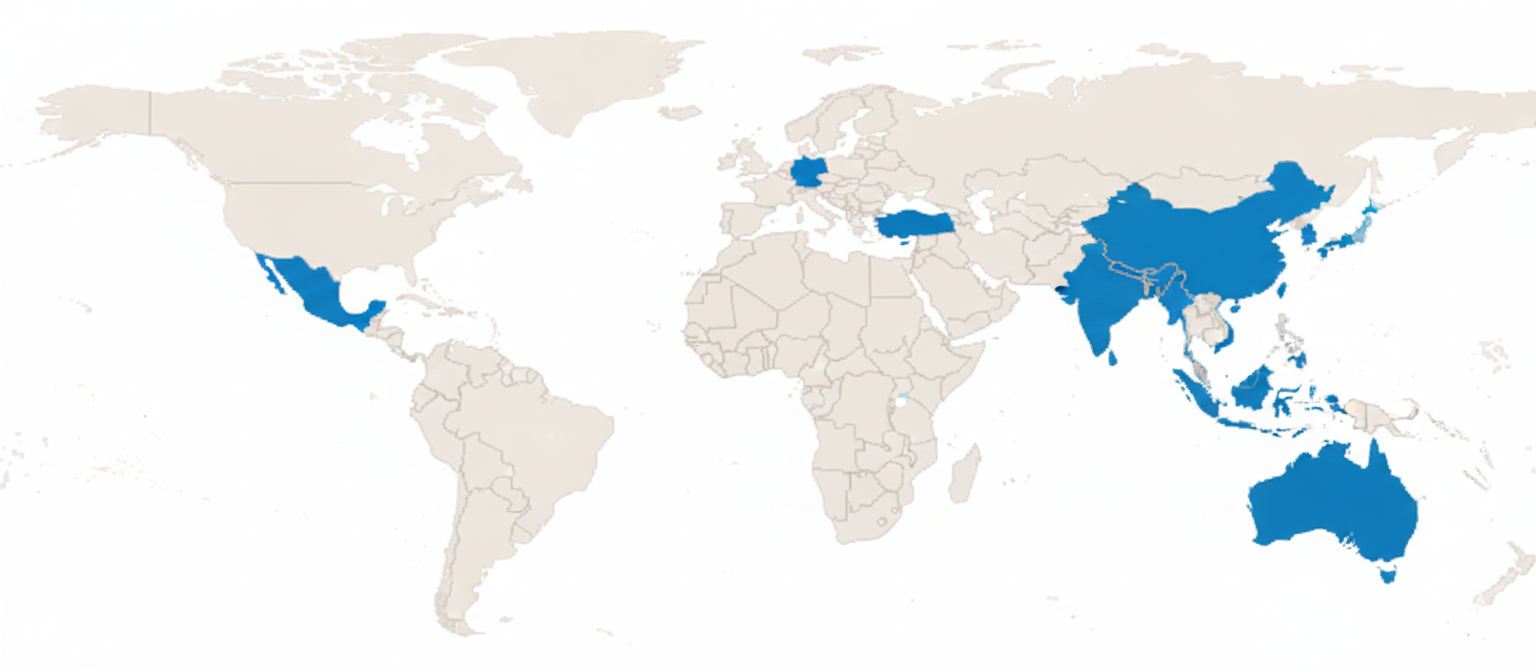

Heaven Engineering is a precision manufacturing company based in Surat, Gujarat. With 7+ years of experience, we specialize in CNC machining, VMC milling, die-mould assembly and custom component manufacturing. Our focus is to deliver highly accurate, durable and industry-grade parts with strict quality control for global clients.

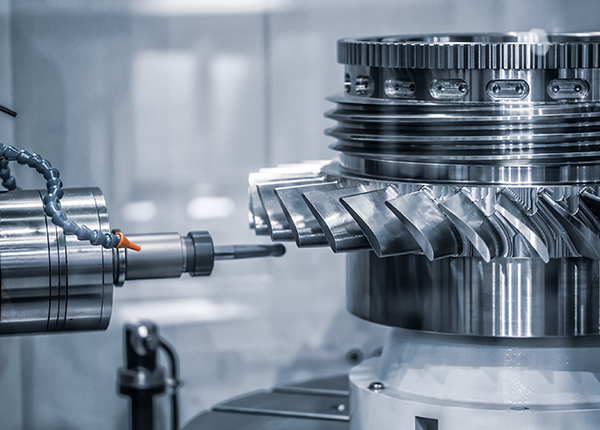

End-to-end CNC machining for prototypes, small batches and large production runs. We deliver dimensionally accurate components built to your drawings.

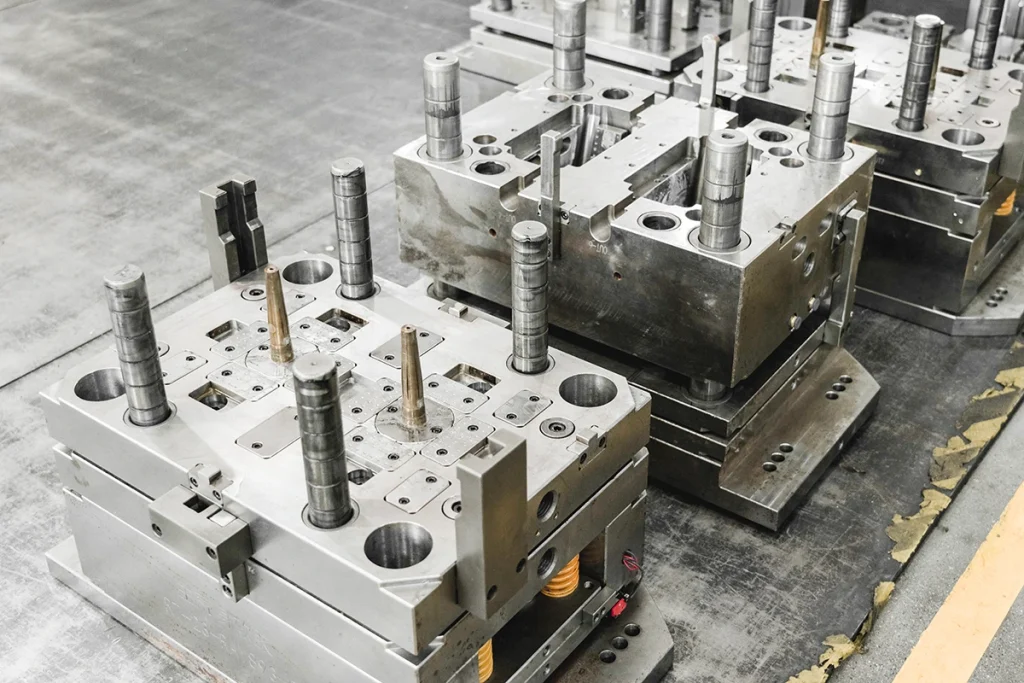

High-quality multi-cavity, vertical, horizontal, blow, and injection moulds with full assembly and testing support.

Precision turned components suitable for multiple industrial applications. Ideal for assemblies and functional parts.

High-accuracy VMC milling for complex shapes, heavy-duty parts and export-grade finishes.

Accurate cutting with minimum waste and zero material wrapping damage. Suitable for sheet metal and custom patterns.

High-precision machining with tight tolerances

Experienced team with 7+ years in manufacturing

Capable of handling all materials (MS, SS, Aluminum, Titanium, Brass, Copper)

Complete service: Design → Machining → Assembly → Inspection

Fast delivery and competitive pricing

Export-ready packaging and processes

We analyze your design, material needs, and production requirements.

CNC/VMC machining, turning, milling, mould assembly, and laser cutting.

Strict quality checks and export-grade packaging for safe delivery.

“Reliable and precise machining partner. Excellent communication and on-time delivery.”

“Reliable and precise machining partner. Excellent communication and on-time delivery.”

Understand how multi-cavity die moulds help manufacturers scale production efficiently. This blog covers mould efficiency, reduced cycle times, improved productivity,...

Learn the key differences between CNC turning and VMC milling. This blog compares material compatibility, accuracy, surface finish, and cost-efficiency...

Discover why precision CNC machining is critical for industries like aviation, pharma, defence, and automotive. This blog explains how tight...

We machine a wide range of materials including Mild Steel (MS), Stainless Steel (SS), Aluminium, Brass, Copper, and Titanium. If you need a special alloy, we can arrange it based on your requirements.

Yes. We handle prototype development, single-piece jobs, small batches, and full-scale production runs depending on client needs.

We accept PDF, DXF, DWG, STEP, IGES, and other standard engineering drawing formats. You can upload your files directly through the contact form.

Lead time depends on the complexity and quantity of the component. Simple parts may take 3–7 days, while custom moulds or large-volume orders may require additional time.

Yes. We offer complete assembly support for die-moulds and components, along with strict inspection and quality checks before final delivery.

Get a free quote or upload your technical drawings now.

+91 98987 83022

info@heavenengineering.in

Plot No.1, Shed No.10, Rashiwala Compound, Opp. Udhna Bus Stand, Udhna, Surat-394 210.

Copyright © 2025 Heaven Engineering. All rights reserved. | Developed by Hintburg.

WhatsApp us